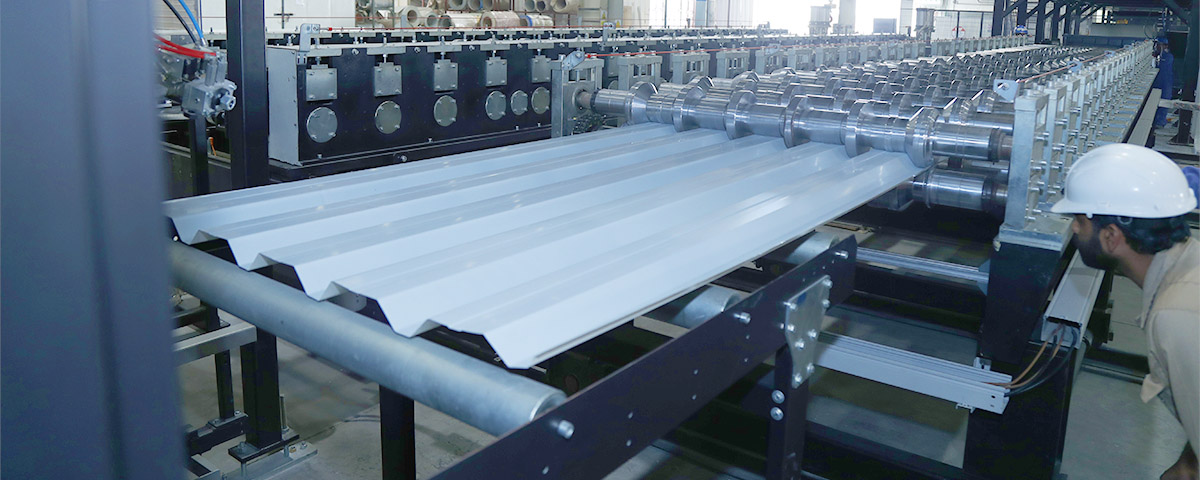

CORRUGATED SHEETS 38/200

Seashore Panels SP38/200 Profile is a leading-edge roofing solution, offering exceptional strength, durability, and adaptability

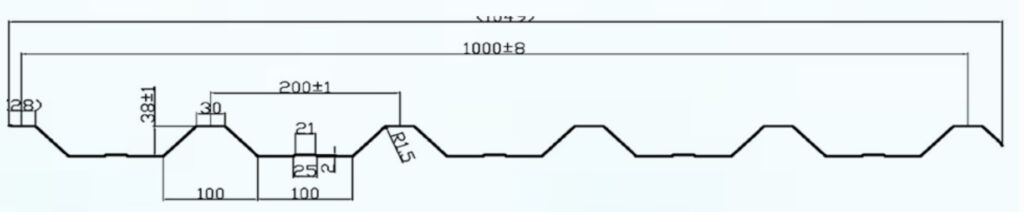

With a 38 mm corrugation depth and 200 mm pitch, Prepainted galvanized steel or aluminum option. Production in various color options. Production flexibility at any ordered length between 2 m – 16 m sheet thickness options 0,40-0,50-0,60-0,70-0,80- 0,90 -1.20mm.